In modern construction, few materials have had as profound an impact as concrete. Its versatility, strength, and durability have made it a cornerstone of our built environment. According to the Cement Concrete & Aggregates Australia (CCAA), “70% of the world’s population lives in a structure that contains concrete,“ underscoring its widespread presence in our daily lives. In fact, concrete is the second most consumed substance on Earth, surpassed only by water.

However, this widespread use comes at a significant environmental cost. The production of cement, a key ingredient in concrete, is a major contributor to global carbon dioxide emissions. Scientific American reports that “Making one kilogram of cement sends one kilogram of CO2 into the atmosphere. Worldwide every year cement and concrete production generates as much as 9 percent of all human CO2 emissions.” This statistic highlights the urgent need for sustainable alternatives in the

construction industry.

The Quest for Sustainable Concrete

In response to these environmental concerns, researchers and industry leaders have been working tirelessly to develop sustainable concrete solutions. But what exactly is sustainable concrete, and how does it differ from its traditional counterpart?

Sustainable concrete, often referred to as “green concrete,” is designed to reduce the environmental impact of construction without compromising on performance. This is achieved through various methods, including:

- Using alternative cementitious materials

- Incorporating recycled aggregates

- Optimizing mix designs for improved durability

- Enhancing the carbon sequestration properties of concrete

Let’s explore these innovations that are shaping the future of construction.

Alternative Cementitious Materials

One of the most promising approaches to creating sustainable concrete is the use of alternative cementitious materials. These substances can partially replace traditional Portland cement, significantly reducing the carbon footprint of the final product.

Fly Ash (AshCrete)

Fly ash, a byproduct of coal combustion, has emerged as a popular supplementary cementitious material. When used in concrete production, it can replace up to 30% of the cement content, reducing CO2 emissions while improving the concrete’s strength and durability. This innovative use of industrial waste not only reduces landfill but also creates a more sustainable construction material.

Blast Furnace Slag

Another industrial byproduct finding new life in sustainable concrete is blast furnace slag. This material, derived from iron production, can replace up to 70% of cement in certain applications. Concrete made with blast furnace slag typically exhibits improved resistance to chemical attack and reduced heat of hydration, making it ideal for mass concrete applications.

Micro Silica (Silica Fumes)

Micro silica, also known as silica fume, is an ultrafine powder produced as a byproduct of silicon and ferrosilicon alloy production. When used in concrete, it can significantly enhance strength and durability. Its ability to reduce permeability makes it particularly useful in applications where water resistance is crucial, such as in marine environments or water-retaining structures.

Innovative Aggregate Replacements

Beyond cement alternatives, sustainable concrete also incorporates innovative aggregate replacements. These materials help reduce the demand for virgin natural resources and often make use of waste products that would otherwise end up in landfills.

Recycled Concrete Debris

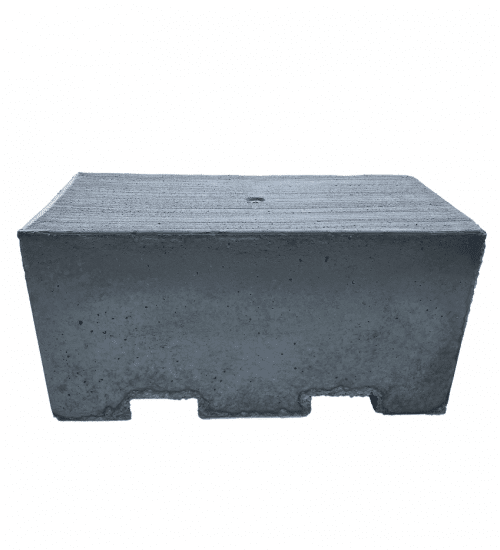

One of the most straightforward ways to make concrete more sustainable is to use recycled concrete as aggregate. This practice not only reduces waste but also decreases the demand for new aggregate mining. Companies like InfraBlock are at the forefront of this trend, incorporating recycled materials into their precast concrete products such as their Interlocking Blocks and Large Interlocking Blocks.

Post-Consumer Glass

Glass, being inert and durable, makes an excellent aggregate replacement in concrete. When finely ground, it can even exhibit pozzolanic properties, contributing to the strength development of the concrete. This innovative use of waste glass not only reduces landfill but also creates unique aesthetic possibilities, as seen in InfraBlock’s Custom Designed Faced Blocks.

Plastic Waste

The use of plastic waste as a partial aggregate replacement is an emerging trend in sustainable concrete production. While it may slightly reduce the strength of the concrete, it offers a valuable way to repurpose non-biodegradable plastic waste. This approach aligns with the circular economy principles that many forward-thinking companies are adopting.

Emerging Technologies in Sustainable Concrete

The quest for more sustainable concrete doesn’t stop at material replacements. Researchers are continually developing new technologies to make concrete itself more environmentally friendly.

Carbon Dioxide Absorbing Concrete

One of the most exciting developments in this field is concrete that can absorb CO2 from the atmosphere. By incorporating special minerals that react with and trap atmospheric CO2, these innovative concretes could potentially transform our built environment into massive carbon sinks.

Self-Healing Concrete

Another promising technology is self-healing concrete. By incorporating bacteria or special polymers into the concrete mix, these materials can automatically repair small cracks as they form. This not only extends the life of concrete structures but also reduces the need for resource-intensive repairs and replacements.

Applications and Benefits of Sustainable Concrete

The applications for sustainable concrete are as varied as those for traditional concrete. From foundations to high-rise buildings, and from roads to retaining walls, sustainable concrete can be used in virtually any construction project.

InfraBlock’s product range showcases the versatility of sustainable precast concrete solutions. Their Interlocking Blocks and Large Interlocking Blocks are ideal for creating sturdy, eco-friendly retaining walls and storage bays. The company’s Capping Blocks provide elegant finishing options for these structures, while their Temporary Fence Feet demonstrate how sustainable concrete can be used even in temporary construction applications.

The benefits of using sustainable concrete extend beyond environmental considerations:

- Improved Durability Many sustainable concrete mixes exhibit enhanced durability, leading to longer-lasting structures and reduced maintenance needs.

- Cost-Effectiveness: While initial costs may be higher, the long-term durability and reduced maintenance requirements of sustainable concrete often result in significant cost savings over the life of a structure.

- Enhanced Performance: Depending on the specific mix design, sustainable concrete can offer improved performance characteristics such as higher strength, better chemical resistance, or enhanced workability.

- Regulatory Compliance: As environmental regulations become stricter, using sustainable concrete can help projects meet or exceed compliance requirements.

Challenges and Future Outlook

Despite its many advantages, the widespread adoption of sustainable concrete faces several challenges. These include:

- Initial Investment: Some sustainable concrete solutions may have higher upfront costs. However, products like InfraBlock’s precast concrete elements often prove more cost-effective in the long run.

- Durability: InfraBlock’s sustainable precast products, such as their Interlocking Blocks and Large Interlocking Blocks, are engineered for longevity. This durability means less frequent replacements and repairs, leading to significant cost savings over time.

- Reduced Labor Costs: The modular nature of products like InfraBlock’s Custom Designed Faced Blocks allows for quicker and easier installation. This efficiency can substantially reduce labor costs during construction.

- Energy Efficiency: In applications like retaining walls or building facades, InfraBlock’s sustainable concrete products can contribute to better insulation and energy efficiency of structures. This can lead to ongoing energy cost savings.

- Minimal Maintenance: The high-quality, controlled manufacturing process of InfraBlock’s precast elements results in products that require minimal maintenance. This reduces ongoing costs associated with upkeep and repairs.

- Versatility and Reusability: Products like InfraBlock’s Temporary Fence Feet showcase how sustainable concrete elements can be reused across multiple projects, spreading the initial investment over several applications.

By considering these long-term benefits, the initial investment in sustainable concrete solutions like those offered by InfraBlock can lead to substantial cost savings over the lifecycle of a structure or project.

2. Technical Complexity: Working with new materials and mix designs can require additional expertise and testing.

3. Industry Inertia: The construction industry can be slow to adopt new technologies, particularly when they involve changes to such a fundamental material as concrete.

However, the future outlook for sustainable concrete is promising. As environmental concerns continue to grow and regulations tighten, the demand for sustainable construction materials is likely to increase. Ongoing research and development are continually improving the performance and cost-effectiveness of sustainable concrete solutions.

The concrete industry stands at a crossroads. The environmental impact of traditional concrete production is unsustainable, but the need for this versatile material continues to grow. Sustainable concrete offers a path forward, allowing us to meet our construction needs while significantly reducing our environmental footprint.

From innovative cementitious materials to creative use of waste products as aggregates, the field of sustainable concrete is ripe with innovation. Companies like InfraBlock are leading the way, demonstrating how sustainable precast concrete products can meet a wide range of construction needs without compromising on quality or performance.

As we look to the future, it’s clear that sustainable concrete will play a crucial role in shaping our built environment. By embracing these innovations, we can continue to build the infrastructure we need while also building a more sustainable future for our planet.